Polycarbonate vs. Acrylic... YOU Decide! |

|

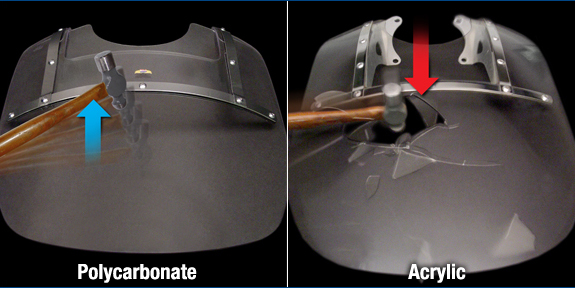

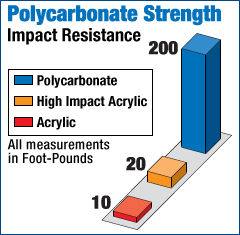

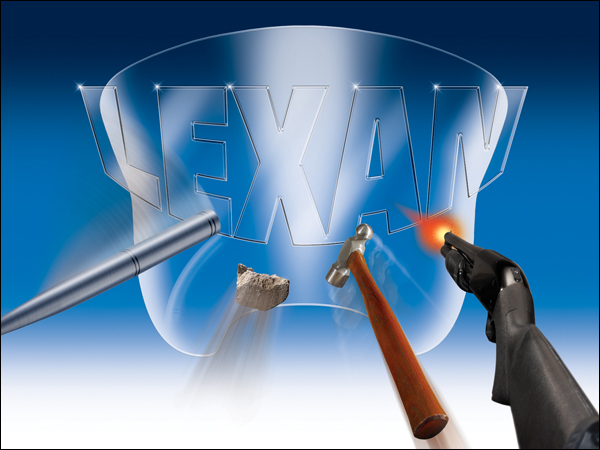

First Use of Lexan® Polycarbonate In 1975, National Cycle was the first company in the world to introduce and use GE’s Lexan® FMR hardcoated polycarbonate material for motorcycle windshields. By using polycarbonate durability and advanced windshield design, the first modern styled, optically clear, custom windshield was made by our company. What are the Benefits of Polycarbonate? Outstanding impact strength! No other thermoplastic comes close to matching the impact strength of polycarbonate, making it the ideal material for motorcycle windshields. It is 20X more impact resistant than acrylic plastic (Lucite®) or "aircraft plastic". You can check the technical data from the Free Falling Steel Dart Test and the IZOD Notch Test but real world testimonials, like the one from a customer who met a ball peen hammer at 75MPH attest to the outstanding impact strength of polycarbonate.

Now when a company claims their windshields are made of "aircraft plastic", keep in mind that the only aircraft that use an acrylic windshield are the diminutive hobby planes like the Piper® Cub. Modern aircraft use polycarbonate... commercial airliners use polycarbonate... military fighter jets use polycarbonate. As a matter of fact, the U.S. Air Force tested acrylic fighter jet canopies compared to polycarbonate canopies (using the famous frozen chicken cannon) and concluded that only polycarbonate met their impact strength requirements.

Watch our "Polycarbonate vs. Acrylic" video. See how the two materials compare when hit by rocks, hammers, baseball bats, 9mm handguns and 12-gauge shotguns. Then YOU decide what material you want your next windshield made from. |